Renewable resources such as solar energy are becoming more and more important in the power supply world. Technology such as photovoltaics is used for their production. Photovoltaic technology is now an integral part of the global energy mix and will play an increasingly important role in the future. This technology already meets the highest standards.

Although the global capacity of photovoltaics will increase by 2035, the market has evolved from the seller to the buyer's market. Necessary adaptations in the technology and value chain ensure access to growth markets. In combination with new components of semiconductor technology, such as transistors with silicon carbide (SiC), high-frequency braid technology secures technology and cost leadership.

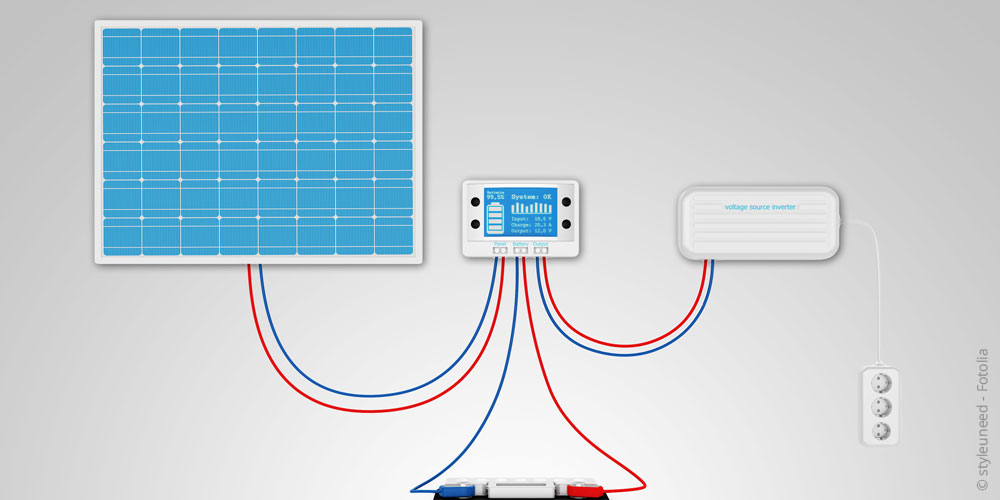

- Inverters

- Wind power

- Power plant suppliers

- Cogeneration

PACK offers special solutions for dynamic markets As a specialized provider of high-frequency strands, PACK covers the entire product range for renewable energies. Typical applications that are already supplied by PACK today are wind power, combined heat and power, photovoltaics, fuel cell technology. Our highly specialized team can help you competently and reliably. In order to meet the challenges of the future - for example in the field of photovoltaics - we are constantly working on the expansion of our product portfolio. The products meet the highest standards of quality and reliability. PACK manufactures exclusively at its production site in Germany. With more than 80 years of manufacturing know-how in the areas of stranding, bandaging, winding, profiling and assembly, PACK is ideally equipped to transform the ideas of its customers into mature product solutions. A high production depth enables rapid sampling according to individual requirements.

In cooperation with a long-term customer, a new generation inverter has been developed. The use of transistors made of silicon carbide (SiC) enabled the design to be realized with optimized performance and an extremely compact design.

The new development was accompanied by a research project in cooperation with the Nuremberg University of Applied Sciences, Faculty for Electromagnetic Fields at the ➔ Friedrich Alexander University Erlangen-Nuremberg. Feasibility analysis showed that specific line frequency mechanisms (skin effect, inner and outer proximity effect) cause significant power losses in the development. Within the framework of joint product development, the electrical properties of the required HF strands were permanently optimized. The individual parameterization with respect to e.g. The number of cores, the outer diameter, the sling length, taking into account the frequency, voltage and other component specifications, was made possible using the Optiscale © litzing data banks.

As a result of the combination of silicon carbide transistor with its good dynamic and static properties and an optimized HF braid, a more compact cooling system could be used. Furthermore, the effect of efficiency on current operating costs was reduced in the form of electricity costs. Compared to a conventional system, the use of the new technology saved up to 40% of operating costs. The higher costs of the new SiC semiconductors could be compensated for on the system level by material savings in the passive components.