Our company started in 1933 with the production of stainless steel and chrome nickel wire.

When the triumph of the TV in the living rooms began in the 1950s, founder Rudolf Pack expanded the product portfolio: We produce copper-coated wire with our own painting machines - since then, the copper lacquer production has been part of our core business.

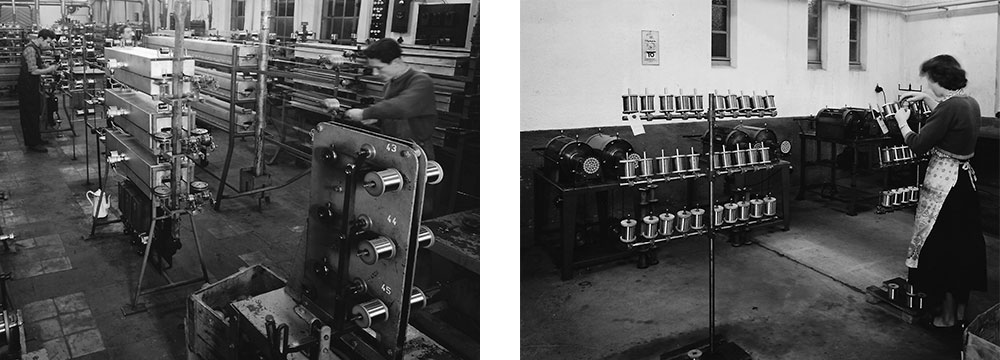

In addition, our special expertise for HF litz wire has a long history. In the late 1950s, we were already producing the first strands at our Gummersbach-Derschlag factory - initially with self-built machines. To date, we are developing those special machines for our litz production.

Since the 1980s, we have concentrated exclusively on the production of copper wire and HF litz wire. During this time, the brand nameRUPALIT®, an acronym derived from Rudolf Pack Litzen, were created and later protected by trademark law.

In 1985, we introduced the → RUPALIT Profile to the market: the cross-section of the strand is not round, but square or rectangular. This increases the copper filling factor and minimizes the space requirement and increases the performance in the corresponding component respectively. This power litz has been developed to meet a specific customer requirement and has opened up a series of customer-initiated innovations, which continues to this day.

In 1991, we have certified the RUPOL and the RUPALIT Braid according to the UL standard. This makes us the first manufacturer of enamelled copper wire with an international security check mark. Gradually many of our products are certified and the certifications are expanded and renewed as required.

In 1999 → RUPALIT Safety revolutionized the market. Thanks to the reinforced outer insulation, no intermediate or layer insulation is necessary. This saves space and weight. At the same time, it reduces the production time of components. This litz design is tested and approved by VDE according to various standards (IEC 60950, IEC 61558).

2002 comes → RUPALIT Planar: The HF Litz design with the large cross-section is particularly suitable for the transmission of high currents.

With → RUPALIT Flecht, we are launching a very wide and flat litz design in the market in 2004. In 2005, a triple extruded single wire follows with → RUPATEX. In 2009, a variant of → RUPALIT Profile for the fully automatic winding of HF litz for photovoltaic products was launched on the market. Further innovations will follow.

All innovations have one thing in common: our customers give us the impetus for their development. They make specifications for winding space, voltage strength, flexibility and frequencies. We then develop prototypes, test and optimize until the perfect product goes into production.

From the extremely fine stainless steel wire to the fine enamelled copper wire and the Litz Wire to the aluminium wire: the development of our products continues.

In 2008, we have launched our first research project "Characterization and optimization of Litz Wire". Together with the Chair for Electromagnetic Fields at the Friedrich-Alexander-University Erlangen-Nuremberg, the company Spezialtransformatoren Stockach GmbH & Co. KG, the Federal Ministry of Economics and Technology and the Forschungszentrum Jülich GmbH, we had been investigating how to reduce proximity and skin effects.

Since the completion of this basic research in 2011, we have extensive data (data on characterization and design of high-frequency litz), which help us to adapt our litz to customer requirements. Our commitment to research and development was honored in 2014 by the German Founders' Association. In addition, there are also numerous publications in renowned scientific magazines (eg IEEE) that confirm the quality of the findings. A special print from the respective electronics SH Power magazine with the most important results can be → ordered directly from us.

From 2015 to 2016, we were investigating the "performance inductors with factor 4 higher performance" with the same partners as in the first research project. This also concerns loss-free current transport and energy efficiency, taking into account optimal thermal conditions.

In the future, we will - in cooperation with partners and customers - increasingly deal with the topic of "Contacting of HF-Litz Wire" in order to develop new solutions for our customers.